A Comprehensive Analysis to Tile Leveling System China

Introduction

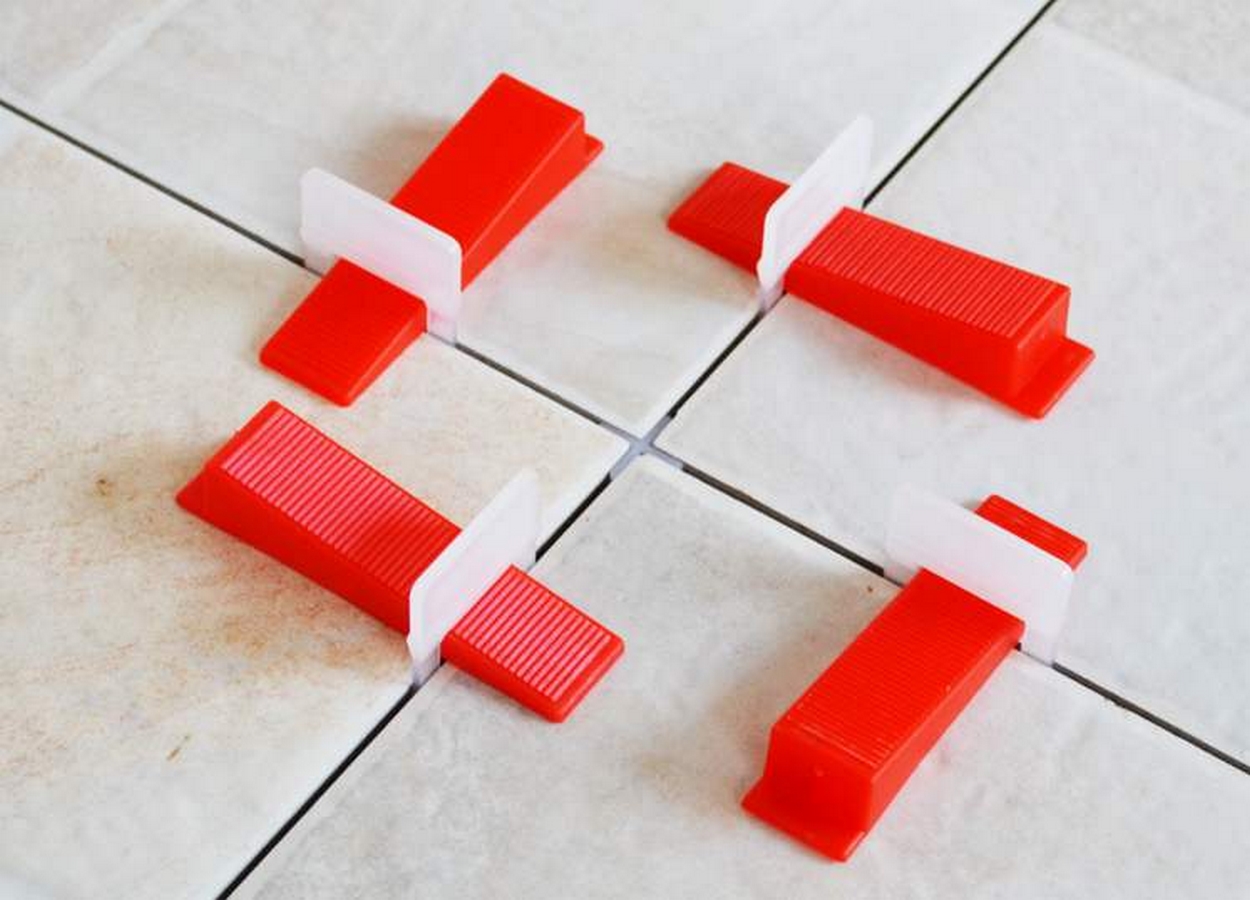

A tile leveling system (TLS) is implemented in a steel mill to make the height of each level uniform. The height varies due to thermal expansion and contraction of steel sheets as well as swelling and shrinkage of grout materials used in tile floors, both horizontally and vertically.

The tile leveling system China adjusts the difference between average floor levels at different places, changing the height of its frame. The TLS can be factory-made or field-constructed according to the section sizes of the level.

The measurements of each level should be done with precision instruments like a laser. The TLS requires minimal maintenance and consists of many parts, which include support frames, leveling gages, adjustable jackscrews.

If you have great interests in the tile leveling system, no matter you are a business owner, or a person who just bought a new house, you have better not miss this article.

The benefits of using a tile leveling system

1. Efficiency

Rather than waiting for the slab to be completely installed before finishing grouting, tiles can be leveled while the slabs are still being laid. The tops of the tiles can be leveled easily by hand with a small leveler and, as the slabs are being laid, the tiles can be grouted.

2. Labor-saving

When there's an imperfection in one part of the slab and it needs to be replaced with another and leveled again, less labor will be required if each replacement area were leveled by hand. This is because the use of a tile leveling system speeds up the process.

3. Time-Saving

Because tiles can be leveled while slabs are being laid, any time saved in laying the slabs will also result in less work. On the other hand, The tile leveling system speeds up the leveling process as well as allowing for adjustments to be made, tiles can be grouted faster which means that there will be less time for the tile layer and supervisor.

4. Flexibility

Other than defects due to poor quality control, mistakes made in installing the slabs, can be corrected while leveling. For example, if a pipe or conduit needs to be laid under one of the slabs and this was not taken into consideration when setting it out then some of the tiles may have to be cut around these obstructions, or the tiles may have to be cut away to lay down an extra pebble bed under one of the slabs.

From the perspective of drawings, using a tile leveling system can also provide certain flexibility. It allows for an installer to make changes to the drawings at any time. The change can be made while checking with management if allowed, and then a new drawing marked up with the changes can be issued before ordering materials or scheduling installation. If installed on-site, a person can make any changes to the drawings while leveling and then order materials or schedule installation of the slab immediately.

Tips for choosing the best type of flooring for your home

Wear Resistant Floors

You should think about the amount of traffic.

If the location in your home gets high traffic and the people that walk on the floors are likely to wear out their shoes quickly, then a durable material that resists abrasion is the best choice.

Laminate Floors

If the floor will be in the kitchen or the bathroom, a hard-wearing and easy-to-clean surface make the most sense. Laminate floors are the perfect option for these areas because they can withstand high moisture levels and chemical cleaners, as well as being less likely than many other materials to break

Wood Flooring

If the location in the place where the floor will be used in a little bit of traffic but not enough to use wear-resistant surface, then the wood floor would be your best choice.

Because the wood floors can be refinished, the cost to maintain the floor is minimal compared to the other types of flooring options.

Ceramic Tile Floors

If the place where the floor will be located has little traffic and the people that walk on the surface are likely not to put a lot of pressure on the area due to the fact that the area is just a walkway.

The tile flooring is the perfect option. You should remember the fact the ceramic tiles are made from the same material used to make many countertops, they are very hard and can be refinished if they need it. As we mentioned above, to the ceramic tile floors, it’s significant for the use of tile leveling system.

Why choose the tile leveling system in China?

The Chinese tile leveling system is a traditional technique using tiles to level the ground. Chinese people have been known for their excellence in leveling techniques since ancient times, which can be seen from the Chinese plane table (a tool used for making horizontal and vertical measurements). That's why the sourcing companies always focus on Chinese manufacturers. It was invented by Chinese craftsmen during the Han Dynasty (206 BC – 220 AD) and it was used to make Chinese maps for over a thousand years.

Tile leveling system China has the advantage of high production efficiency, compact structure, low noise level, long service life, easy maintenance, etc., That’s why leveling system made in China is very popular with customers from all over the world. With a wide range of tile width and length, they can be manufactured based on the needs of Customers.

The tile leveling system in China is a non-invasive, faster, and more cost-effective approach to floor leveling. Chinese levelers are typically made of aluminum alloy channels attached to the bottom of ceramic or porcelain tiles to achieve appropriate floor levels in the support of Chinese tile leveling screws. Chinese leveler systems can be used for Leveling Acrylic Floors Tile Stairs, Ceramic Tile Floors, Wooden Flooring, and Porcelain Flooring.

Chinese leveling systems are very effective in leveling out floor variations up to 0.5-1.0 mm. The Chinese tile leveling system is mostly used on level ground situations or first floors where concrete finishing slabs are cast to desired levels.

6 Reliable Companies for Tile Leveling System China

FOSHAN WINSEN BUILDING MATERIAL CO., LTD

It is an enterprise with the manufacture and rich export experience, boasting an area of 10,000 Square meters and over a hundred employees.

Equipped with advanced aluminum extrusion lines, Anodizing lines, powder coating spray& wooden grain production lines, deep fabrication lines, etc. The daily production capacity has broken through 80,000 pieces.

A professional R&D team, excellent management, rich export experience, all of these advantages enable us to provide satisfied service to the customers.

They insist on independent innovation, focusing on high-grade aluminum trims production. With over 10 years of development in the global market, their business has expanded to the region including Europe, South America, Middle East, Asia...etc.

Haider

Established in early 2000, Haider has dedicated to the manufacturing of bridge bearing, decorating materials, and another kind of products.

With over 200 experienced staff now in the company, Haider boasts an area of 50,000 square meters and a construction area of 20, 000 square meters.

Owning advanced production and quality testing equipment, Haider is one of the leading companies in China even in Global. The company passes the ISO9001:2008 international quality system certification and ISO 14001: 2004 environmental management system certification.

Based on the requirement of projects, Haider can design and manufacture different products.

With the support of a strong technical force, a professional installation team, and excellent after-sales service, Haider has won a global reputation. Its products have been used in various projects, including

Pudong International Airport, Beijing Capital International Airport, and Hangzhou International Airport, Chengdu International Airport, Xi′an International Airport; Shanghai Maglev, Shanghai light rail, light rail Beijing, Nanjing Metro; Shanghai Hongqiao hub, and Guiyang six broad river bridge, Hunan Zhuzhou Xiangjiang River Bridge, Wuhan Tianxingzhou Yangtze River Bridge, Zhejiang Zhujiajian Bridge.

The customers of Haider nowadays come from different countries and southeast Asia, the Middle East, Africa, Australia, South America, and many other countries and regions

FOSHAN WINSEN BUILDING MATERIAL CO., LTD

It is an enterprise with the manufacture and rich export experience, boasting an area of 10,000 Square meters and over a hundred employees.

Equipped with advanced aluminum extrusion lines, Anodizing lines, powder coating spray& wooden grain production lines, deep fabrication lines, etc. The daily production capacity has broken through 80,000 pieces.

A professional R&D team, excellent management, rich export experience, all of these advantages enable us to provide satisfied service to the customers.

They insist on independent innovation, focusing on high-grade aluminum trims production. With over 10 years of development in the global market, their business has expanded to the region including Europe, South America, Middle East, Asia...etc.

BEAUTRIM

Established in 2002,Beautrim specializes in producing building decorative products.

Stainless steel has been one kind of popular new material. Beautrim has embraced the new technology to products the products in the material of stainless steel.

Nowadays, Beautrim products have been exported to various countries and regions.

To stand out among its peers, beautrim has located its marketing position, owning the widest production line. Beautrim always tries to provide the best quality-price products and professional service to our customers in the field of construction.

Foshan Sanshui Match Hardware Product Co., Ltd

Foshan Sanshui Match Hardware Product Co., Ltd is an integrated company that includes production, processing, and sales of hardware products.

Our main business is production, processing, and sales of hardware products, as well as import and export services of various decorative materials and various commodities and technologies. Currently, exports of aluminum extrusions to the EU exceed 6,000 tonnes per year, and we have successfully entered the EU Aluminium alloy Anti-dumping Partnership list, where we enjoy favorable anti-dumping rates.

We have complete production management, with our own anodizing, extrusion, coloring, CNC, sand machine, cutting, stamping shop, and equipment. Always good at customization.

Marvel engineering works

Established in 2007, Marvel engineering Works are dedicated to the manufacturing of Z clip, Carpet profiles, laser cutting grill, and other products.

To satisfy the need of our valuable customers, Their products can be customized into different specifications.

Besides, Marvel engineering works can make the promise to the product quality with the support of the professional team.

The company’s client-oriented service, easy payment option, timely delivery, and transparent dealing have won a great reputation in the global market.

Zhaoqing YIDA Aluminum Technology Co., Ltd

As a distributor of aluminum products, YIDA always focuses on the market trend and leads the R&D team to develop new products.

The first factory was established in 2005 with only 10 people at that time. With the development of its technology and expansion of product lines, YIDA has become one of the leading companies in its area, which integrates research, design, production, sales.

Nowadays, based in ZhaoQing High-tech area, YIDA boasts an area of 10000 square meters for its different processing workshops.

Equipped with 25 tons of punching production lines, 5 CNC engraving machines, 50 modern oxidation tanks, YIDA can provide various technology in mold development, extrusion, anodizing, single and double salt coloring, and other processes to the customers.

Conclusion

Through this article, we have shared our experience about the tile leveling system, including

the introduction to the tile leveling system

The benefits of using a tile leveling system

Tips for choosing the best type of flooring for your home

Why choose the tile leveling system in China?

6 reliable companies for tile leveling system China

We hope that you can get the information you need from this article. If you have other questions, please feel free to contact us. Thanks for your reading!