Guide to Tile Trim Essentials|That you need to know.

Introduction

Understanding the materials used for tile trim is essential for choosing the right option to meet your specific needs.

Many homeowners and professionals often wonder about the best available options and their unique features.

This article commits to addressing these inquiries by exploring six different materials commonly used for tile trim: aluminum, PVC, wood, ceramic, stainless steel, and vinyl.

Each material offers distinct advantages and characteristics, making it crucial to select the right one for your project.

Join us as we delve into the features of these materials, helping you make an informed decision for your next renovation or construction endeavor.

Aluminum Tile Trim

- Material

Aluminum tile trims are crafted from high-quality aluminum alloys, such as 6063 and 6061, known for their strength and corrosion resistance. This lightweight material simplifies both installation and transportation, making it a popular choice in the construction and decoration sectors. - Common Types

Aluminum tile trims are available in various configurations, including:

- L-shaped trims:Ideal for connecting walls and floors.

- T-shaped trims:Perfect for joining two tiles of the same height.

- Corner trims:Designed to protect and enhance outer and inner corners.

- Transition strips:Facilitate smooth transitions between different floor heights.

- Possible Surface Treatments

To enhance both aesthetics and durability, aluminum tile trims can undergo several surface treatments:

- Anodizing:Increases corrosion resistance and surface hardness.

- Painting:Provides a range of colors to suit various decor styles.

- Brushed finish:Adds texture, aligning well with modern minimalist designs.

- Common Lengths

Aluminum tile trims are typically available in lengths of 2.5 meters and 3 meters. Custom lengths can also be arranged based on specific project requirements. - Common Thickness

The thickness of aluminum tile trims usually ranges from 0.8mm to 2.0mm, chosen based on the installation environment and tile dimensions. - Common MOQ

The minimum order quantity (MOQ) for aluminum tile trims generally falls between 100 and 500 pieces, varying by manufacturer and product type. Custom orders may require a higher MOQ. - Uses

Aluminum tile trims serve multiple purposes:

- Protecting tile edges:Prevents damage and wear.

- Aesthetic decoration:Enhances visual appeal and provides a neat finish.

- Transition treatment:Ensures seamless transitions between different materials or heights.

- Advantages and Disadvantages

Advantages:

- Durability:Resistant to corrosion, ensuring longevity.

- Lightweight:Easier to handle compared to other metals.

- Variety:Available in multiple types and finishes to meet diverse needs.

Disadvantages:

- Cost:Generally more expensive than plastic trims.

- Temperature sensitivity:May expand or contract with extreme temperature changes.

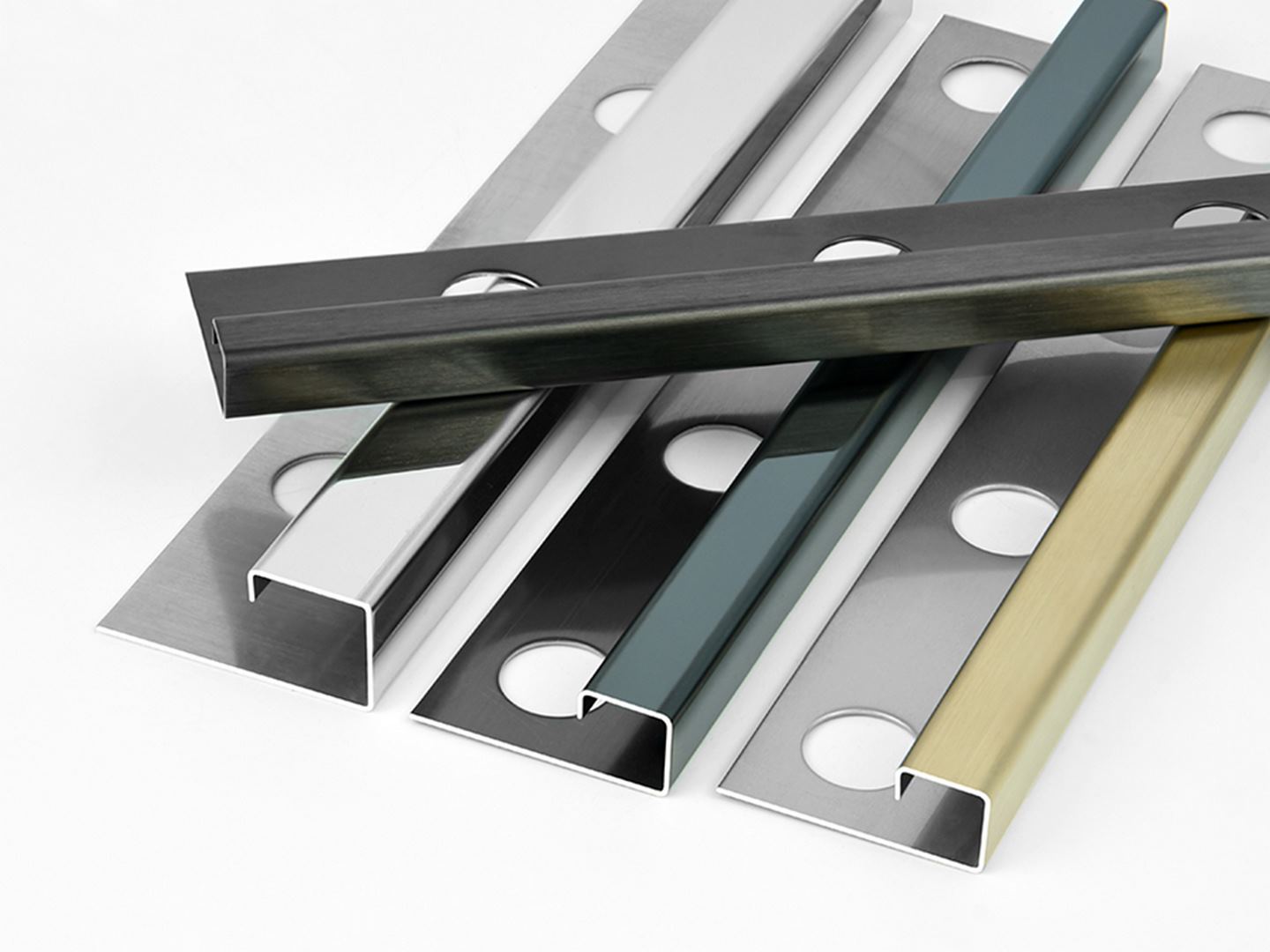

Stainless Steel Tile Trim

- Material

Stainless steel tile trims are primarily crafted from 304 or 316 stainless steel. The 304 grade is suitable for general indoor applications, while 316 is recommended for humid or corrosive environments, such as kitchens and bathrooms, due to its superior corrosion resistance and strength. - Common Types

Stainless steel tile trims come in various configurations, including:

- L-shaped trims:Ideal for connecting walls and floors.

- T-shaped trims:Perfect for joining two tiles of the same height.

- Corner trims:Designed to protect and enhance outer and inner corners.

- Transition strips:Facilitate smooth transitions between different materials or heights.

- Possible Surface Treatments

To enhance both aesthetics and durability, stainless steel tile trims can undergo several surface treatments:

- Brushed finish:Offers a subtle texture, ideal for modern interiors.

- Mirror polishing:Increases glossiness, suitable for high-end decor.

- Painting:Available in various colors to match different design styles.

- Common Lengths

Stainless steel tile trims are typically available in lengths of 2.5 meters and 3 meters, with some manufacturers offering custom lengths to meet specific project requirements. - Common Thickness

The thickness of stainless steel tile trims generally ranges from 0.5mm to 2.0mm, with selections based on the installation environment and tile dimensions. - Common MOQ

The minimum order quantity (MOQ) for stainless steel tile trims usually falls between 100 and 300 pieces, depending on the manufacturer and product type. Custom products may require a higher MOQ. - Uses

Stainless steel tile trims serve multiple purposes:

- Protecting tile edges:Prevents damage and wear.

- Enhancing space aesthetics:Adds a modern touch, improving overall decor.

- Transition treatment:Ensures seamless transitions between different materials or heights.

- Advantages and Disadvantages

Advantages:

- Corrosion resistance:Superior protection in humid environments.

- High strength:Capable of withstanding significant pressure and impact.

- Aesthetic appeal:Available in brushed or mirror finishes, suitable for various design styles.

Disadvantages:

- Higher cost:Generally more expensive than plastic or aluminum trims.

- Temperature sensitivity:May experience thermal expansion under extreme temperature variations.

Rubber Edge Trim

- Material

Rubber edge trims are primarily made from either synthetic rubber or natural rubber. Synthetic options, such as EPDM (ethylene propylene diene monomer), offer excellent weather and chemical resistance, while natural rubber is known for its superior elasticity and flexibility. These properties make rubber edge trims suitable for a variety of environments. - Common Types

Rubber edge trims are available in several configurations, including:

- U-shaped trims:Ideal for covering and protecting edges on various surfaces.

- L-shaped trims:Used for connections between walls and floors, providing both aesthetics and protection.

- Closed trims:Effective for sealing and dustproofing, particularly for door and window frames.

- Possible Surface Treatments

Surface treatments for rubber edge trims are generally straightforward and include:

- Coloring:Available in a wide range of colors to complement different decor styles.

- Texturing:Enhances surface friction, reducing the risk of slipping.

- Common Lengths

Rubber edge trims are typically offered in lengths of 2 meters and 3 meters, with some manufacturers providing custom lengths to accommodate specific project requirements. - Common Thickness

The thickness of rubber edge trims generally ranges from 1mm to 5mm, with choices depending on the intended use and environmental conditions. - Common MOQ

The minimum order quantity (MOQ) for rubber edge trims usually falls between 100 and 500 pieces, varying by manufacturer and product type. Custom products may have a higher MOQ. - Uses

Rubber edge trims serve multiple functions:

- Protecting edges:Prevents sharp edges from causing injury to people or damage to objects.

- Enhancing space aesthetics:Provides a clean appearance that improves overall decor.

- Sealing and dustproofing:Offers effective sealing at doors and windows, preventing dust and moisture entry.

- Advantages and Disadvantages

Advantages:

- Flexibility:Rubber materials easily adapt to various edge shapes.

- Non-slip:The rubber surface provides excellent friction, minimizing slip hazards.

- Durability:High-quality rubber exhibits good wear and aging resistance.

Disadvantages:

- Temperature sensitivity:Rubber may harden or become brittle in extreme temperatures.

Water absorption: Certain types of rubber can absorb water, potentially affecting performance.

Plastic Edge Trim

- Material

Plastic edge trims are primarily made from three types of plastic: polyethylene (PE), polyvinyl chloride (PVC), and polypropylene (PP). Each material offers unique characteristics:

- Polyethylene (PE):Known for its flexibility and impact resistance, making it suitable for a variety of environments.

- Polyvinyl chloride (PVC):Offers good chemical resistance and is suitable for both indoor and outdoor applications, all while being relatively inexpensive.

- Polypropylene (PP):Lightweight and heat-resistant, making it ideal for high-temperature environments.

- Common Types

Plastic edge trims are available in several configurations, including:

- U-shaped trims:Designed to cover and protect edges on various surfaces.

- L-shaped trims:Used for connections between walls and floors, providing both aesthetic appeal and protection.

- Closed trims:Effective for sealing and dustproofing, particularly for door and window frames.

- Possible Surface Treatments

Surface treatments for plastic edge trims include:

- Coloring:Available in a wide range of colors to match different decor styles.

- Texturing:Enhances surface friction, reducing the risk of slipping.

- Common Lengths

Plastic edge trims are typically offered in lengths of 2 meters and 3 meters, with some manufacturers providing custom lengths to meet specific project requirements. - Common Thickness

The thickness of plastic edge trims generally ranges from 1mm to 5mm, with options tailored to the intended use and environmental conditions. - Common MOQ

The minimum order quantity (MOQ) for plastic edge trims typically ranges from 100 to 500 pieces, varying by manufacturer and product type. Custom products may have a higher MOQ. - Uses

Plastic edge trims serve multiple functions:

- Protecting edges:Prevents sharp edges from causing injury to people or damage to objects.

- Enhancing space aesthetics:Provides a clean, finished appearance that improves overall decor.

- Sealing and dustproofing:Offers effective sealing at doors and windows, preventing dust and moisture from entering.

- Advantages and Disadvantages

Advantages:

- Lightweight:Plastic materials are easy to handle, making installation and transportation straightforward.

- Corrosion resistance:Good chemical resistance makes plastic edge trims suitable for various environments.

- Cost-effectiveness:Generally more affordable compared to metal or rubber trims.

Disadvantages:

- Poor temperature resistance:Plastic may deform or melt in high-temperature environments.

Lower strength: The strength and wear resistance of plastic edge trims are typically less than those of metal or rubber materials.

Vinyl Edge Trims

- Material

Vinyl edge trims are primarily composed of polyvinyl chloride (PVC), known for its excellent chemical and weather resistance. This makes vinyl trims suitable for both indoor and outdoor applications. To enhance durability and flexibility, vinyl edge trims often incorporate UV stabilizers and plasticizers. - Common Types

Vinyl edge trims are available in several configurations, including:

- U-shaped trims:Designed to cover and protect edges on a variety of surfaces.

- L-shaped trims:Ideal for connections between walls and floors, providing both aesthetic appeal and protection.

- Closed trims:Effective for sealing and dustproofing, particularly in door and window frames.

- Possible Surface Treatments

Surface treatments for vinyl edge trims include:

- Coloring:Available in a wide range of colors to match different decor styles.

- Texturing:Increases surface friction, enhancing aesthetics while preventing slipping.

- Printing:Custom patterns or logos can be printed on the surface to boost brand identity.

- Common Lengths

Vinyl edge trims are typically offered in lengths of 2 meters and 3 meters, with some manufacturers providing custom lengths to accommodate specific project requirements. - Common Thickness

The thickness of vinyl edge trims generally ranges from 1mm to 5mm, with options tailored to the intended use and environmental conditions. - Common MOQ

The minimum order quantity (MOQ) for vinyl edge trims typically ranges from 100 to 500 pieces, varying by manufacturer and product type. Custom products may have a higher MOQ. - Uses

Vinyl edge trims serve multiple functions:

- Protecting edges:Prevents sharp edges from causing injury to people or damage to objects.

- Enhancing space aesthetics:Provides a clean, finished appearance that improves overall decor.

- Sealing and dustproofing:Offers effective sealing at doors and windows, preventing dust and moisture from entering.

- Advantages and Disadvantages

Advantages:

- Corrosion resistance:Vinyl materials exhibit excellent chemical resistance, making them suitable for a variety of environments.

- Lightweight:Their relatively low weight makes installation and transportation straightforward.

- Cost-effectiveness:Generally lower in price compared to other materials, making them suitable for large-scale applications.

Disadvantages:

- Poor temperature resistance:Vinyl may deform or degrade under extreme temperatures.

- Lower strength:Compared to metal or certain rubber materials, vinyl edge trims typically have lower strength and wear resistance.

Foam Edge Trims

- Material

Foam edge trims are typically made from three primary materials: polyethylene (PE), polyurethane (PU), and ethylene-vinyl acetate (EVA). These materials are known for their excellent flexibility and cushioning properties, effectively absorbing impacts and providing protection. - Common Types

Foam edge trims come in various configurations, including:

- Self-adhesive trims:Equipped with adhesive backing for quick and easy installation.

- U-shaped trims:Designed to cover and protect edges on various surfaces.

- L-shaped trims:Ideal for connections between walls and floors, offering both aesthetic appeal and protection.

- Possible Surface Treatments

Surface treatments for foam edge trims include:

- Coloring:Available in a range of colors to match different decor styles.

- Texturing:Enhances surface friction, improving aesthetics and reducing slipping risks.

- Printing:Custom patterns or logos can be printed on the surface to enhance brand identity.

- Common Lengths

Foam edge trims are typically offered in lengths of 2 meters and 3 meters, with some manufacturers providing custom lengths to accommodate specific project requirements. - Common Thickness

The thickness of foam edge trims generally ranges from 3mm to 10mm, with options tailored to the intended use and environmental conditions. - Common MOQ

The minimum order quantity (MOQ) for foam edge trims typically ranges from 100 to 500 pieces, depending on the manufacturer and product type. Custom products may have a higher MOQ. - Uses

Foam edge trims serve multiple functions:

- Protecting edges:Prevents sharp edges from causing injury to people or damage to objects.

- Cushioning:Effectively absorbs impacts, protecting items from damage.

- Sealing and dustproofing:Provides effective sealing at doors and windows, preventing dust and moisture from entering.

- Advantages and Disadvantages

Advantages:

- Good flexibility:Foam materials adapt well to various edge shapes, ensuring a snug fit.

- Lightweight:Their relatively low weight simplifies installation and transportation.

- Strong cushioning:Excellent impact absorption protects items from potential damage.

Disadvantages:

- Poor temperature resistance:Foam may deform or degrade under extreme temperatures.

- Wear susceptibility:Compared to metal or certain plastic materials, foam edge trims generally exhibit lower wear resistance.

Conclusion

In this article, we explored six types of edge trims: Aluminum, Stainless Steel, Rubber, Plastic, Vinyl, and Foam. Each material offers unique benefits tailored to specific needs.

- Aluminum provides durability and corrosion resistance, ideal for high-traffic areas.

- Stainless Steel offers strength and a sleek finish, perfect for modern aesthetics.

- Rubber ensures cushioning and flexibility, protecting against impacts.

- Plasticis lightweight and cost-effective, suitable for various applications.

- Vinyl combines chemical resistance with aesthetic versatility, enhancing decor.

- Foam excels in cushioning and sealing, effectively absorbing impacts and preventing dust ingress.

These edge trims address common issues such as safety from sharp edges, aesthetic enhancement, moisture prevention, and overall durability, making them essential components in construction and design.

Welcome to know more detailed information about products in WINSEN.